As warehouse automation continues to gain momentum in supply chain, what sort of impact can we expect for the workforce? With workers and automation both responsible for moving materials, it can be difficult to nail down the relationship between them.

Putting Automation into Play

As labour shortages persist, warehouse automation is on the rise. 49 per cent of supply chain professionals report that they will add automation within the next five years.

While some warehouse employees may view automation as a threat to their job security, that’s rarely the case. With the right technology in place, warehouse management teams can elevate their productivity and take their operations to new heights.

A KÖrber survey found that 41 per cent of supply chain professionals said they still use spreadsheets for manual data entry. While manual data entry can certainly be effective, it introduces the potential for data logging errors.

Even without inaccuracies in data entry, employees must spend hours meticulously entering data — a process that is often as monotonous as it is time-consuming. Many warehouses also use manual processes for receiving, storing, picking, packing, and shipping to customers.

As employees pour their efforts into these tedious tasks, speed, accuracy, and customer satisfaction rates plummet in tandem with employee engagement.

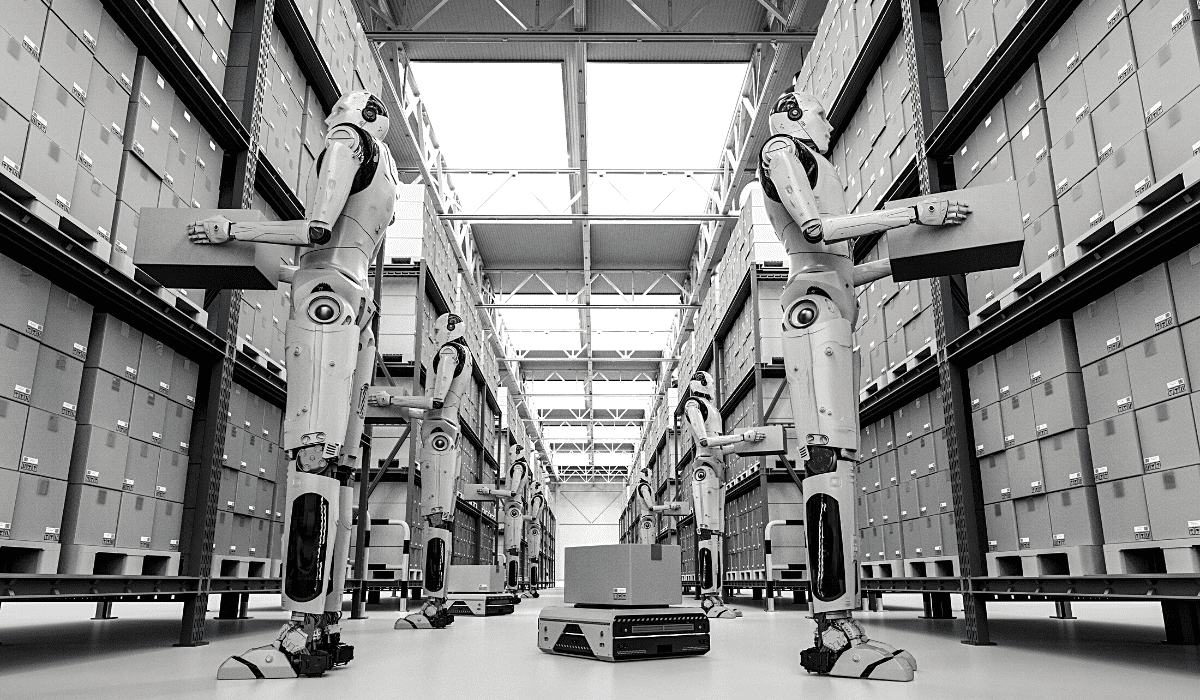

This is where automation comes into play. Automation and robotics technologies, including palletizers, sortation systems, autonomous mobile robots (AMRs), automatic guided vehicles (AGVs), and more are designed to move materials throughout a warehouse, pick and put away products, and refill shelves as needed. Other warehouse technologies include process-oriented automation software that leverages scanners, barcodes, and more to streamline the data collection and integration process.

Combined, these technologies help supply chain leaders address labour gaps while allowing frontline employees to do their jobs efficiently and effectively, freeing up time for more value-add work.

Cultivating the Perfect Partnership

The future of warehouse management is not about choosing between humans and warehouse automation — it’s about combining the two. Many robots are specifically designed with human-machine collaboration in mind.

Businesses need employees on the warehouse floor who can work with these new technologies, troubleshooting technical issues and serving as machine operators and specialists.

With the right warehouse automation and supply chain robotics by their side, employees can spend more time on challenging, thought-provoking tasks, and less time on monotonous or dangerous ones.

Bastian Consulting is a boutique search practise that concentrates on sourcing leaders that deliver change across the Asia Pacific, we have the expertise to source leaders that can transform your business and thrive in times of rapid change.

To know more, you can reach out to me on +61 (0) 409 090 434 or tony@bconsult.io

Source: Korber