In supply chain the ability to accurately forecast is crucial. And effective forecasting is only possible if you have access to good quality information. So being informed ahead of time that a critical shipment is likely to be delayed or a key component is likely to be unavailable for a set period can have huge financial implications for your business.

This type of vital information is available ahead of time is now becoming routine among supply chain organisations that are embracing the Big Data revolution currently taking place in the industry.

The Big Advantage

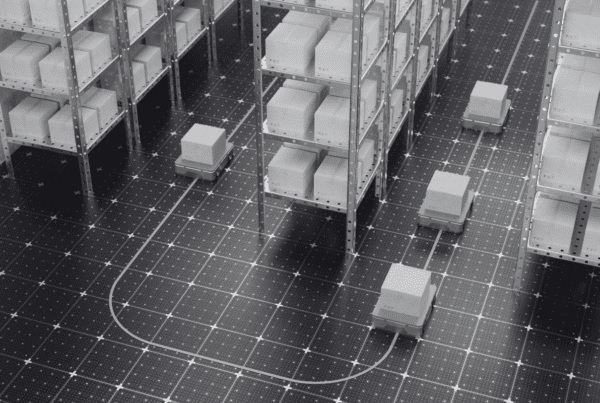

Internet of Things (IoT) and artificial intelligence-based analytics can be used to predict asset maintenance requirements and avoid unscheduled downtime. IoT can also provide real-time production and shipping data while GPS-driven data combined with traffic and weather information allows for dynamically planned and optimised shipping and delivery routes. These types of examples provide a glimpse into the possibilities and advantages that Big Data can offer in increasing the agility and efficiency of supply chain operations.

Big Data solutions can also be used to support integrated business planning and to better understand market trends and consumer behaviours. The integration of product sales, social media trends, and demographic data from multiple data sources provide the capability to accurately predict and plan supply chain actions. This can help navigate the tricky path between overstocking or running out of products that are in high seasonal demand

The Big Future

There are hurdles to overcome and challenges involved with transitioning to Big Data powered operations but supply chain companies that embrace the technologies will enjoy huge first-mover advantages over the competition.

The Big Conversation

Transformational innovation and change come with the need to bring new knowledge and skills into your business. To arrange a conversation about what these changes mean for hiring supply chain leaders, click here.