There’s no handbook for the COVID-19 crisis and no single solution for factories and distribution centres when returning to work. Employees in sectors such as food distribution and medical supplies have spent the last few months working harder than ever while braving the unknown and adapting continually to a stressful situation.

Social distancing, access, sanitation, local regulations and more — virtually every aspect of the business model needs to be rethought to ensure the safety of employees and prevent a new wave of the virus. This means executing health and safety plans and considering opportunities for what comes next.

Above all else, leaders must put humans at the centre of any plans, and lead with empathy, humility and respect.

You can think about this for your supply chain in two phases: physical return to work and work reimagined.

During the pandemic, there has been increased scrutiny and pressure on certain industries, factories and distribution centres to continue making and delivering food, medical supplies, cleaning supplies and other everyday items safely.

But for those that have not been operating at all, or only at partial capacity, a physical return is not as simple as opening the company doors. Putting people front and centre means first considering the safety, security and well-being of returning employees, whether they are plant floor supervisors, machine operators, warehouse workers or forklift and truck drivers.

There will be new supply chain processes and new considerations; there is no more business as usual. Instead, businesses need to focus on seeing operations through a future-back lens (e.g., using tomorrow’s models to guide today’s actions) and building resilience into their operations as they do it.

According to EY, here are four steps to physical return to work for factories and distribution centres:

1) Understand and assess your business. Consider the following questions:

• Who should come back and when?

• Is remote work viable for some or all roles?

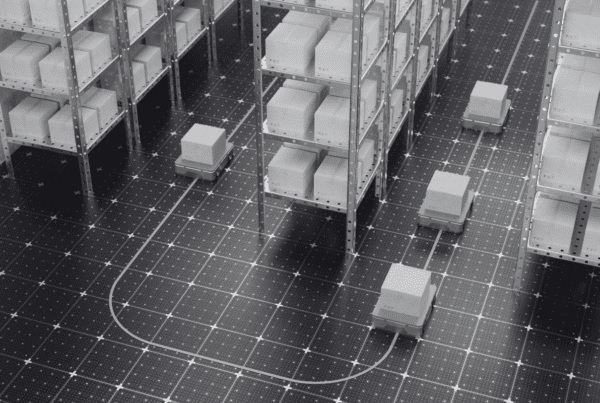

• Is automation of some functions helpful?

• How do we focus on our employees’ physical and mental health?

2) Create a command centre to help you prepare for and recover from unforeseen events in the future. The command centre will need to be staffed with people with the right skills. Its first order of business should be creating a factory or distribution centre reopening playbook for health, hygiene and operational continuity.

3) Implement technology to assist in improving safety. For example, use mobile check-in applications instead of having employees clock in and clock out. Invest in a labour-management system to manage scheduling and determine workforce requirements by activity area.

4) Prepare the physical space. Establish and communicate clear policies on workplace social distancing; meeting protocols; and health, hygiene and daily cleaning and disinfection requirements. Consider starting the day on a staggered schedule to prevent contact between too many employees while entering and exiting the facility.

For distribution centres, it will be important to limit outside access to facilities, including drivers. Look for ways to minimize human interaction and avert bottlenecks at the gate and reception areas. Consider driver self-check-in, license plate scanning and other yard-management technology.

Companies that focus on creating long-term value with humans at the centre, technology at speed and innovation at scale will be successful in the new futur

Bastian Consulting is a boutique search practise that concentrates on sourcing leaders that deliver change across the Asia Pacific, we have the expertise to source leaders that can transform your business and thrive in times of rapid change.

To know more, you can reach out to Tony on +61 (0) 409 090 434 or tony@bconsult.io